05

2023

-

09

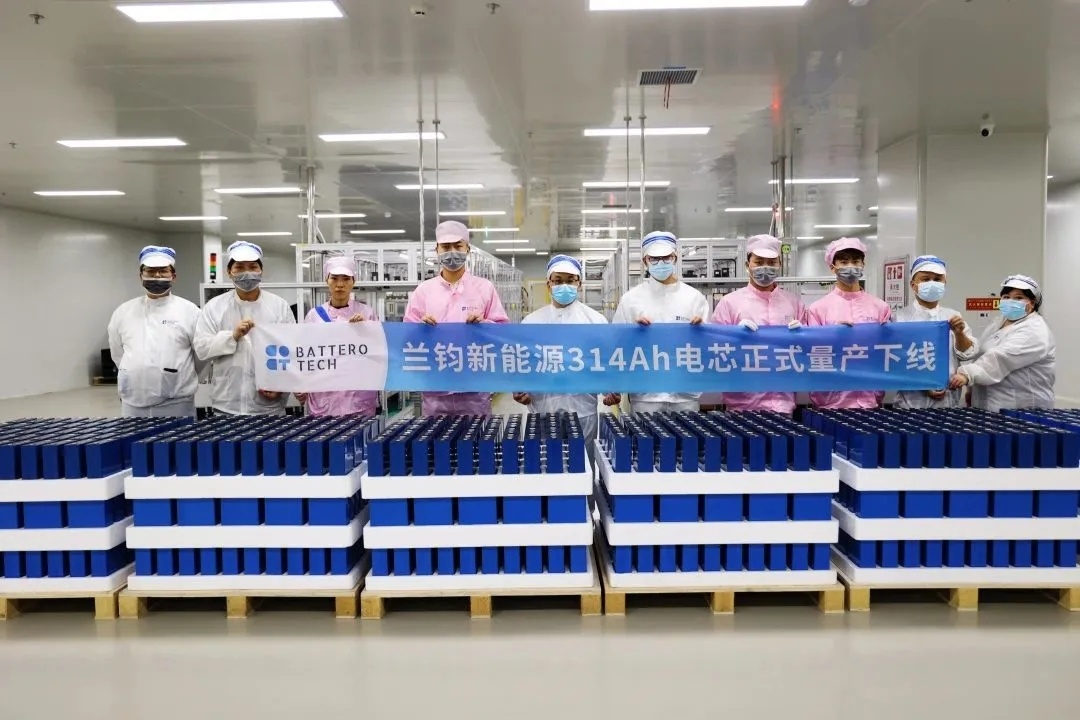

BatteroTech Rolls off Mass Production Line of First-batch 314Ah Battery Cells

Affiliated Classification:

【 summary description 】

BatteroTech has recently unveiled its mass production of 314Ah battery cells as celebrated by a roll-off ceremony on September 4th, 2023. Since the inception of the BatteroTech 314Ah battery cells advertised as “operating at 1 precise kWh, and being ultimate cost-effective” on May 24th, 2023, the product was the first to finish rolling off the first-batch mass production line within 3 months alone.

As always, BatteroTech adheres to the standardized single-cell format, modularization of battery modules, and multifaceted compositions of systems, and has opted to develop upgraded products with the same format as the 280Ah battery cell in order to build the large-storage energy storage products of the next generation.

On the industry front, the energy storage battery cells of the 71173 format are compatible with mainstream large-capacity energy storage products and can be commercialized as tested by the market. Meanwhile, battery manufacturers seek an improved battery cell performance of the same format, which means a certain degree of economic efficiency and universality in the manufacturing link and in matching downstream clients.

Upon determining the standardized format, opting for which battery capacity is another critical step since it is the key to differentiating the “next-generation energy storage products” at BatteroTech.

Nevertheless, it marks a simple start to shape energy storage battery cells that cater to this well-established market demand for “large-capacity” battery products. The next significant step is to keep up with the demands from downstream clients and establish an enclosed business loop for products.

BatteroTech respectively filtered and assessed 300Ah, 306Ah, 315 Ah, and other capacity specifications in a systemic manner to decide on the large-capacity specification to adopt.

BatteroTech, upon in-depth rounds of arguments, has drawn the conclusion from the perspective of end products that depooling the battery cell capacity will “wring out” the fishy content of the battery nominal as if the water were removed for calculating the net weight. This helps meet the clients’ demands for ultimate cost-efficiency. Consequently, 314Ah was finally identified as the next-generation upgraded product for 280Ah battery cells and the research, development, and testing of 314Ah battery cells were kicked off swiftly.

High energy, long cycle life, and high safety are all incorporated into the BatteroTech 314Ah battery cell that can realize a 190Wh/kg energy density, a 96% energy efficiency, and the ability to run over 10,000 cycles of cycle life and a discharging capacity retention rate of above 90% at -30℃.

BatteroTech 314Ah battery cell features the chemical system design of the brand-new generation as the next-generation product of the company’s large-capacity energy storage. In detail, it has a storage life of ≥20 years @ 80% EOL, and a first-year retention rate at or above 95% under the application working conditions of 1 cycle each day, prominently boosting the user experience of BatteroTech products at the client end.

BatteroTech 314Ah battery cell can run over 10,000 cycles and exhibits high safety and outstanding comprehensive performance represented by a high energy density of 190Wh/kg, and an energy efficiency of over 95%. Such performance breakthroughs are mainly attributed to BatteroTech’s ingenious R&D endeavors in major components like cathode and anode materials and electrolytes.

BatteroTech opts for the interface modification technology for micro/nano-level cathode and anode materials to considerably lower the occurrence of negative reactions. Cathode materials enable a high compaction design with granularity selection while anode materials stabilize the SEI membrane by the encapsulation and reshaping design on the surface structure.

On the use of electrolytes, BatteroTech employs the self-adapting SEI-forming (solid electrolyte interphase) electrolyte additives and self-healing interfaces for regulation. It substantially cuts the consumption of active lithium with the help of low-expansion materials and interface materials hardening.

On the safety front, the BatteroTech 314Ah battery cell has passed the safety experiments for various purposes like over-charge and over-discharge, extrusion, needle penetration, short circuit, thermal runaway, and limit hot box. Moreover, BatteroTech has reduced the battery weight as each 314Ah battery cell is weighted below 5.55 kg, making the weight obtained after the system integration manageable and thus efficiently alleviating the “burden” and ensuring safety for the system structural design, transport, and installation in the follow-up stages.

It is worth noting that BatteroTech 314Ah battery cell has been accredited by a number of authorized institutions in China and abroad and obtained accredited certifications such as UN38.3, UL1973, UL9540A, and IEC62619. BatteroTech is projected to receive its GB/T36276 certification at the beginning of 2024, showing its endeavors to empower more diverse markets.

It is impossible to harvest new products through overnight research and development. In particular, faced with the intense market competition fueled by multiple models of 30Ah battery cells with large capacity in the energy storage market, only by ensuring responsive market judgments along with swift product R&D and mass production could battery manufacturers lead the market and stand out from competitors. In response to this, the success of the speedy mass production of the BatteroTech 314Ah battery cell manifests the company’s independent thinking toward the energy storage market and more importantly, aligns with the actual demands from end products and clients, which will definitely make the product a market darling.